Back to my Clock, Watch and Lathe Courses

| P/N | NAME | WT. | PRICE |

| 3700 | Rotary Table | 8 lb. | $250.00 |

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part he can design. The only limits are size, not complexity.

Sherlines rotary table is a precision piece of equipment that has been designed to work with Sherlines vertical milling machines; however, it can be used on any mill whenever the small 4-inch size would be an advantage.The table is 2" high and 4" (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherlines 3- and 4-jaw chucks to be mounted directly to the rotary table. An optional right angle attachment is available (P/N 3701) to mount the table in the vertical position to further increase its versatility. With the table mounted vertically, an optional adjustable right angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

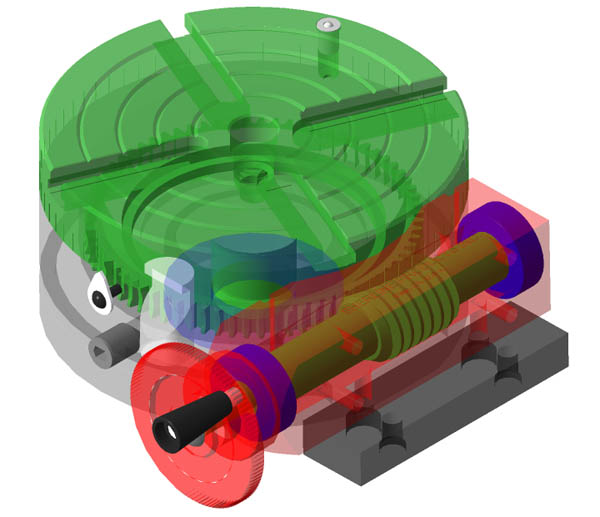

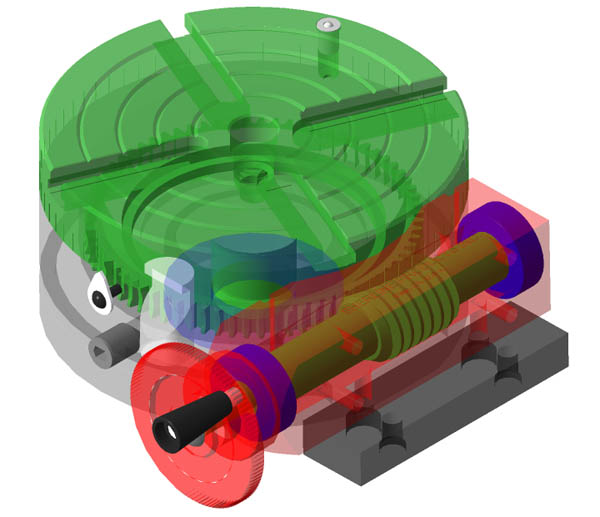

A ghost view of the rotary table shows the internal mechanism so you can see how the worm gear drives the table.. Ball bearings are shown in dark blue.

The rotary table has a unique table locking mechanism that is positive and does not move the table as it is locked. (See the white notched cylinder and gray set screw in the ghost view above.) To maintain accuracy and frictionless movements, ball bearings (dark blue in ghost view above) are used. Worm gears are factory greased and the drives sealed to keep out chips and dirt. An oiler is easily accessible to facilitate lubrication of the table. The appearance is instrument quality with a black oxide base, precision ground finishes and laser engraved markings.

As with all Sherline tools, the illustrated instructions are very useful. The 6-page manual covers the basics of rotary table use and takes the user through a typical project.

Any machinist who wants to take his capabilities to the ultimate levels should consider purchasing and learning to use a rotary table. The Sherline rotary table is an extremely precise and well-built piece of equipment that is sized to fit with our product line. It can also be useful on larger equipment when its compact size is called for.

The rotary table is now also available with a stepper motor mount attached ready for the application of a stepper motor and CNC controls. See P/N 3700CNC. Please note that it is NOT possible to upgrade a manual P/N 3700 rotary table to a P/N 3700-CNC later on. To maintain the required degree of accuracy, the base of the rotary table and the worm housing are ground as a pair in the production process. It would not be possible to maintain this level of accuracy if a CNC worm housing were to be bolted to a table for which is was not specially ground. While kits are available to convert any Sherline lathe or mill to CNC stepper motor mounts, no such kit is available for the rotary table. A new unit must be purchased.

RETURN TO ACCESSORIES MASTER LIST

Shop for Sherline LATHES

Shop for Sherline MILLING MACHINES

RETURN TO My Home Page

| Home

Page | Frequently

Asked Questions | Testimonials

| Lathes

|

| Mills

| Accessories

|

Tool

Prices | Accessory

Prices |